3D Printer Extruder

I bought a 3D printer from 3DStuffMaker as it advertised large build volume of 200mm X 200mm X 200mm and was supposed to be working out of the box. It was intended to be a tool for 3D printing rather than another project, however the unit was largely a failure due to the extruder design and hot end nozzle. After many emails with Australian and Indian support, and Skype calls to India, it became apparent that the performance I expected and what 3DStuffMaker considered acceptable were worlds apart.

After designing, producing and replacing the original extruder, it became apparent that there was a real problem with the hot end as the extruder would stall unless the temperature was very high, and even then there was creaking sounds from the extruder under load.

By placing a piece of filament into the top of the original hot end and forcing it through by hand, I estimate it required ~15kg of force to make it flow. It should be like pushing a hot knife into butter.

The nozzle needed to be replaced, and therefore a new x carriage was needed to mount it.

The Budaschnozzle 2.0 was selected for its rave reviews among 3D printing forums for reliability, accuracy and serviceability. It can be upgraded using improved insulators to achieve temperatures suitable for polycarbonate and nylon.

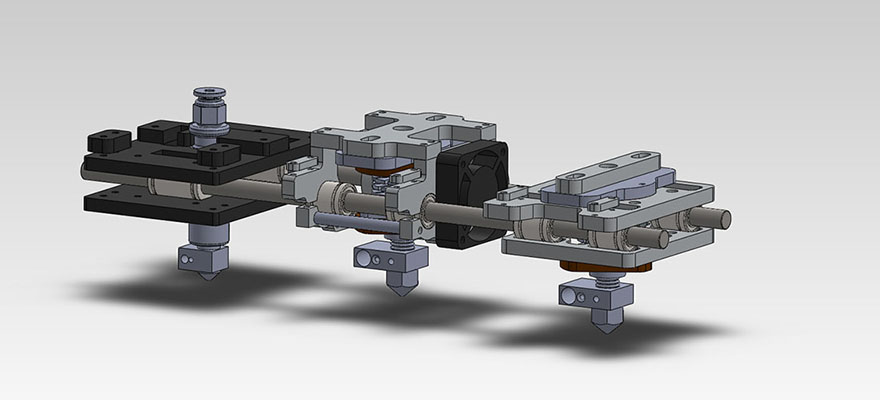

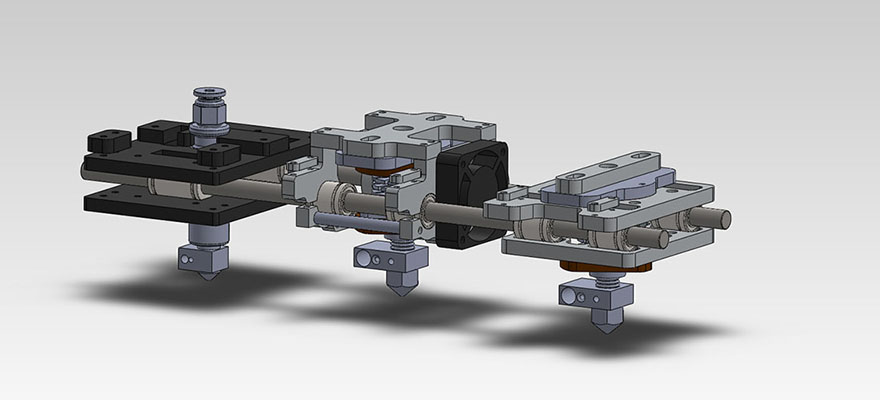

2 options were drawn in CAD, one similar to the original extruder, which has few parts and is easy to produce. The second type was harder to produce but is smaller, allowing for larger x-axis travel and can include 40mm fans for added cooling.

The second option was selected and laser cut in lieu of CNC routed I no longer had access to a CNC router. This presented issues for the design as the edges of laser cut parts can be rough, and tapered. This required refinishing with a hand router and files to achieve perpendicular edges for joins.

The replacement x-carriage and Budaschnozzle perform extremely well. Currently only single wall/vase like objects can be printed as the extruder cannot yet retract filament.

Future improvements could include insulator upgrade, water cooling and multiple hot ends for multi filament support.

Check out the photos below:

|